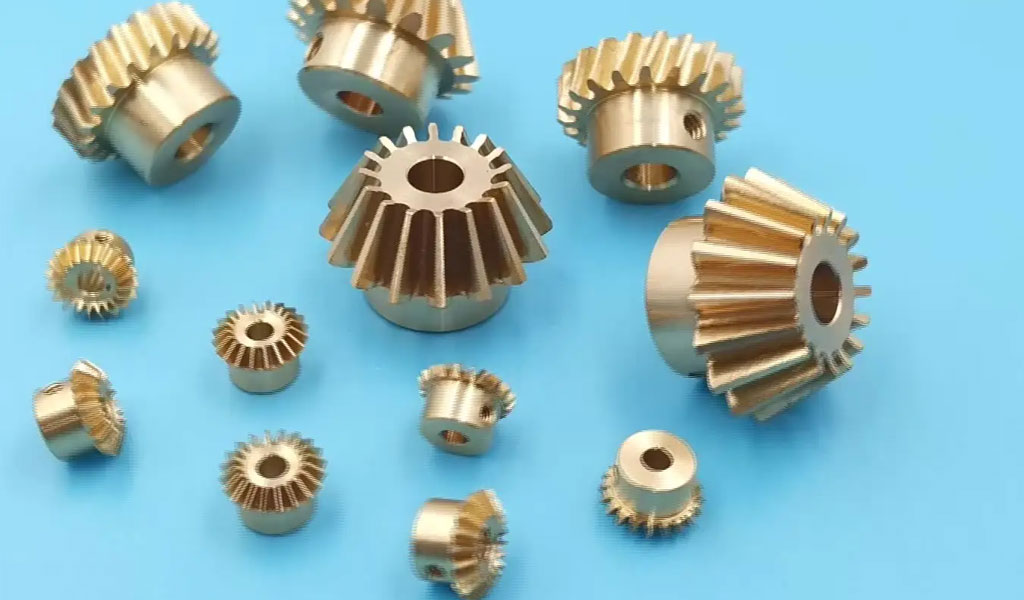

مائڪرو گيئر جي پيداوار ڇا آهي؟

mike ڀٽائيs refer to small ڀٽائيs with diameters ranging from several millimeters to tens of millimeters. They are widely used in fields such as micro mechanical devices, medical equipment, electronic products, and precision instruments.

سمجھاڻي

Micro gears refer to small gears with diameters ranging from several millimeters to tens of millimeters. They are precision machined with high precision and high torque transfer capabilities. Microgears play a key role in microdevices and precision engineering, providing reliable power transmission and precise motion control for a variety of applications.

پيداوار جا حالات:

Manufacturing micro gears requires special production conditions and precision equipment. High-precision CNC machine tools, advanced grinding technology and precision measuring tools are necessary to produce micro gears. In addition, strict quality control and precision debugging are also keys to ensuring the quality and performance of micro gears.

صنعت جو طريقو

There are various methods of جي تياري جي صنعت gears, common ones include:

- 1. سي اين سي مشين: CNC machine tools are used to perform precise cutting and shape processing to achieve the accuracy and quality requirements of gears.

- 2. Precision grinding: Grinding technology is used to process gears to obtain higher precision and surface quality.

- 3. Electrical discharge machining: The principle of electric spark discharge is used to process and modify the shape of gears, which is suitable for the manufacture of micro gears.

نتيجي ۾

As an important part of modern precision engineering, micro gears play a key role in various fields. Through precise manufacturing processes and high-quality materials, micro gears can achieve precise power transmission and motion control, providing reliable support for the normal operation of micro devices and precision instruments. With the continuous development of technology, the manufacturing process and performance of micro gears will continue to improve, bringing more possibilities to future micro engineering innovations.

Through the research and application of micro gears, we can better understand their importance and realize their great potential in different fields. Whether in the field of micromachines, the medical device industry or electronics manufacturing, microgears play an indispensable role. However, micro-gear manufacturing also faces some challenges and difficulties.

First of all, the size and precision requirements of micro gears are very high, which places higher requirements on the manufacturing process. Manufacturing micro gears requires the use of high-precision equipment and tools, such as tiny cutters and grinding wheels. The debugging and maintenance of these equipment also require highly professional skills and experience.

Secondly, material selection is critical to the performance of microgears. Micro gears need to have high strength, wear resistance and low friction coefficient to ensure their stable operation for a long time. Selecting the right materials and applying appropriate heat and مٿاڇري جو علاجs are key to ensuring microgear performance.

In addition, the production cost of microgears is higher, mainly due to the complexity of the manufacturing process and the high investment cost of the required equipment. This also makes the customization and mass production of micro gears face certain challenges.

However, with the continuous advancement of technology and improvements in manufacturing processes, micro-gear manufacturing is moving towards more efficient and precise manufacturing. The research and development and application of new materials, advanced processing technology and the application of automated production technology will help reduce costs, improve production efficiency and quality stability.

In general, micro gears, as an important part of the modern engineering field, have broad application prospects and development potential. Through continuous innovation and technological progress, we are confident that we can overcome the current difficulties and challenges, enable China-made micro gears to maintain a competitive advantage in the global market, and bring more opportunities and achievements to all walks of life.

rيهر Stateپائي جو بيان: جيڪڏھن ڪي خاص ھدايتون ناھن ، ھن سائيٽ تي س articlesئي آرٽيڪل اصل آھن. مھرباني ڪري rinپائيءَ جو ذريعو ظاھر ڪريو: https: //www.cncmachiningptj.com/,thanks

3، 4 ۽ 5-محور سڌائي CNC مشيني خدمتن لاء ايلومينيم مشيننگ، بيريليم ، ڪاربان اسٽيل ، مگنيشيم ، ٽائنيانيم مشيننگ، Inconel ، پلاٽينم ، superalloy ، acetal ، polycarbonate ، فائبر گلاس ، graphite ۽ ڪا.. 98 انچ تائين مشيني حصن جي قابل. ۽ +/- 0.001 اندر. سnessي رواداري. عملن ۾ شامل آھن ملنگ ، ٽرننگ ، ڊرلنگ ، بورنگ ، ٿريڊنگ ، ٽيپ ڪرڻ ، formingاھڻ ، گوڏا کوڙڻ ، جواب ڏيڻ ، جوابي inkingن ،ڻ ، ريمنگ ۽ ليزر ڪٽڻ. ثانوي خدمتون جهڙوڪ اسيمبلي ، سينٽرل پيس ڪرڻ ، گرمي علاج ڪرڻ ، ڪوٽنگ ۽ ويلڊنگ. پروٽوٽائپ ۽ گھٽ کان و volume حجم جي پيداوار پيش ڪئي و maximum ۾ و 50,000 XNUMX،XNUMX يونٽن سان. مناسب فلائيڊ پاور ، نيوميٽڪس ، هائيڊروولڪس ۽ والو ايپليڪيشنون. ايرو اسپيس ، جهاز ، فوجي ، طبي ۽ دفاعي صنعتن جي خدمت ڪري ٿو. PTJ حڪمت عملي youاھيندو توھان کي توھان جي ھدف تائين پھچڻ ۾ مدد لاءِ بھترين قيمتن واريون خدمتون مهيا ڪرڻ لاءِ ، خوش آمديد اسان سان رابطو ڪريو ( sales@pintejin.com ) سڌو توهان جي نئين منصوبي لاءِ.

3، 4 ۽ 5-محور سڌائي CNC مشيني خدمتن لاء ايلومينيم مشيننگ، بيريليم ، ڪاربان اسٽيل ، مگنيشيم ، ٽائنيانيم مشيننگ، Inconel ، پلاٽينم ، superalloy ، acetal ، polycarbonate ، فائبر گلاس ، graphite ۽ ڪا.. 98 انچ تائين مشيني حصن جي قابل. ۽ +/- 0.001 اندر. سnessي رواداري. عملن ۾ شامل آھن ملنگ ، ٽرننگ ، ڊرلنگ ، بورنگ ، ٿريڊنگ ، ٽيپ ڪرڻ ، formingاھڻ ، گوڏا کوڙڻ ، جواب ڏيڻ ، جوابي inkingن ،ڻ ، ريمنگ ۽ ليزر ڪٽڻ. ثانوي خدمتون جهڙوڪ اسيمبلي ، سينٽرل پيس ڪرڻ ، گرمي علاج ڪرڻ ، ڪوٽنگ ۽ ويلڊنگ. پروٽوٽائپ ۽ گھٽ کان و volume حجم جي پيداوار پيش ڪئي و maximum ۾ و 50,000 XNUMX،XNUMX يونٽن سان. مناسب فلائيڊ پاور ، نيوميٽڪس ، هائيڊروولڪس ۽ والو ايپليڪيشنون. ايرو اسپيس ، جهاز ، فوجي ، طبي ۽ دفاعي صنعتن جي خدمت ڪري ٿو. PTJ حڪمت عملي youاھيندو توھان کي توھان جي ھدف تائين پھچڻ ۾ مدد لاءِ بھترين قيمتن واريون خدمتون مهيا ڪرڻ لاءِ ، خوش آمديد اسان سان رابطو ڪريو ( sales@pintejin.com ) سڌو توهان جي نئين منصوبي لاءِ.

- 5 محور مشيننگ

- سي اين سي ملنگ

- سي اين سي موڙيندڙ

- مشيني صنعت

- مشيني پروسيس

- مٿاڇري جو علاج

- ڌاتو مشيننگ

- پلاسٽڪ مشينري

- پائوڊر ميلاجيڪل مولڊ

- مائن جي معدنيات

- پارٽس گيلري

- پاڻمرادو ڌاتو حصا

- مشينري جا حصا

- ايل ايل هوٽسڪي

- عمارت جا حصا

- موبائل حصا

- طبي حصا

- اليڪٽرانڪ حصا

- درزي جي مشيني

- سائيڪل جا حصا

- ايلومينيم مشيننگ

- Titanium مشيني

- اسٽينلیس اسٽيل جي مشين

- ٽامي جي مشيني

- ٽامي جي مشينري

- سپر اللوائي مشيني

- مشيني مشيني

- UHMW مشيني

- Unilate مشيني

- PA6 مشيني

- PPS مشيني

- Teflon مشيني

- اندروني مشينون

- اوزار اسٽيل مشيني

- وڌيڪ مواد